20 Types of Screws and Their Applications

Have you ever thought about that tiny and little but powerful thing that keeps things attached? That is called screws, which help to join and attach a material to a different material like wall to shelves.

We’ve different types of screws that you can use in daily life, like building shelves, tables, and chairs. From common ones like flathead and Phillips screws to specialized ones like hex bolts and carriage screws, each type serves a unique purpose.

Let’s reveal the secrets of screws, how they work, what they’re made of, and what materials they can handle. They do more than join materials; they create strong bonds that last.

These stunning different types of screws can use in unexpected places, from fixing furniture to constructing buildings. These humble fasteners play an important role in making our lives easier and safer.

By the end, you’ll be able to know more about the screws that are around you.

1. Black Truss Screws

Modified truss screws are flexible fasteners designed for wood-to-metal applications. Their unique truss head provides a large surface area for distributing load, making them ideal for joining metal plates to wooden structures.

The screws come with self-drilling points, eliminating the need for pre-drilling holes, which saves time and effort during installation. Additionally, their sharp threads offer grip and pull-out resistance, ensuring a long-lasting and secure connection.

These types of screws for metal are used in the construction industry for projects involving metal roofs, metal framing, and general wood-to-metal connections.

The combination of their easy installation, sturdy hold, and reliable performance makes modified truss screwsa popular choice for both the construction field and DIY projects. Whether you are a professional contractor or a do-it-yourself enthusiast, these screws will ease your work and provide the confidence of a job well done.

2. Concrete Screws

Concrete screws, also known as Tapcon screws, are specialized fasteners designed to securely anchor materials to solid, brick, or block surfaces.

They have a unique thread design that provides an excellent grip on masonry materials without the need for pre-drilling, making them an efficient choice for time-sensitive projects. Concrete screws often come with corrosion-resistant coatings, making them suitable for both indoor and outdoor applications, even in harsh weather conditions.

These different types of screws are commonly used in construction, carpentry, and DIY projects to attach fixtures, electrical boxes, and other items to concrete surfaces.

Their ease of use, reliability, and ability to withstand tough environments make them a preferred choice for professionals, ensuring projects stay in place for years to come. Whether you are working on a home improvement project or a large-scale construction project, these concrete screws offer the peace of mind that your installations will endure the test of time.

3. Hanger Screws

Hanger Screws are hybrid fasteners featuring a wood screw thread on one end and a machine screw thread on the other, offering adaptability for various applications. The wood screw end is used to securely fasten into the wood, providing a strong and dependable hold.

Meanwhile, the machine screw end is suitable for accepting a nut or threaded insert, making them ideal for assembling furniture, cabinetry, and other woodworking projects. Hanger bolts are known for their durability and ability to withstand heavy loads, ensuring a reliable connection between wood and metal or plastic components.

These types of screws are helpful for best screws for woodworking projects and fastening applications, especially when a strong and stable bond is required for structural unity. Whether you are a professional carpenter or a hobbyist, having hanger bolts in your toolkit opens up possibilities for creating and fixing objects with strong and enduring doors, windows.

4. Sheet Metal Screws

Sheet metal screws are specifically designed to secure metal sheets and thin materials with ease and accuracy. They feature sharp, fine threads that provide a secure grip on metal surfaces, reducing the risk of material damage during installation.

These types of screws for metal come in various head styles, including pan, flat, and oval heads, each suitable for different applications, offering flexibility to meet specific project requirements. Sheet metal screws are commonly used in HVAC installations, automotive assembly, and general metalworking projects, proving their usefulness across various industries.

Their wide range of sizes and options, coupled with their ability to drill metal easily, make them a popular and reliable choice for securing thin materials, ensuring projects are completed with efficiency. Also, some sheet metal screws are coated with anti-harm materials, extending their lifespan and making them suitable for outdoor applications.

5. Masonry Screws

Masonry screws are heavy-duty bolts designed to support materials on concrete, brick, or stone surfaces, providing strength and durability. Their hard steel construction and corrosion-resistant coatings ensure its performance even in challenging outdoor environments. Masonry screws are easy to install, combining the convenience of regular screws with the good condition that is required for demanding masonry applications.

These types of screws are widely used in construction, landscaping, and home improvement projects to attach outdoor fixtures, signs, and brackets to masonry surfaces securely.

With their reliability and adaptability, masonry screws have become an important choice for any masonry-related task, offering peace of mind that structures remain as it is for long periods. Moreover, some masonry screws feature zigzag threads that improve their grip on masonry surfaces, providing even greater holding power.

6. Tamper-Proof Screw

Tamper-proof screws are special screws that prevent unapproved access and tampering. They have unique heads that need special tools for installation and removal, making them difficult to tamper with.

These types of screws are commonly used in high-security places like electronic devices and access panels to protect against damage and unauthorized repairs. They are important in industries where safeguarding sensitive information and advantage is crucial. These tamper-proof screws often have markings or serial numbers, making it easy to identify and track individual components.

This feature helps with accountability and detects any attempts at tampering or reproduction. Furthermore, tamper-proof screws can come with different security levels, allowing users to choose the appropriate level of protection for their specific needs.

7. Pan-Head Screws

Pan-head screws have rounded, slightly domed heads with a flat bottom, making them easy to recognize. They are adjustable and work well in various projects, providing strong and stable connections.

These screws are great for soft and brittle materials like plastic, as the flat-bottomed head prevents surface damage during tightening. They are commonly used in carpentry, electronics, and household applications. Pan-head screws come in different materials, such as stainless steel, brass, and zinc-plated options.

This variety allows you to choose the right pan-head screw for specific environmental conditions, reducing the risk of corrosion and ensuring long-lasting performance. Additionally, some pan-head screws have a combination of Phillips and slotted drives, providing users with the option to use different types of screws for installation convenience.

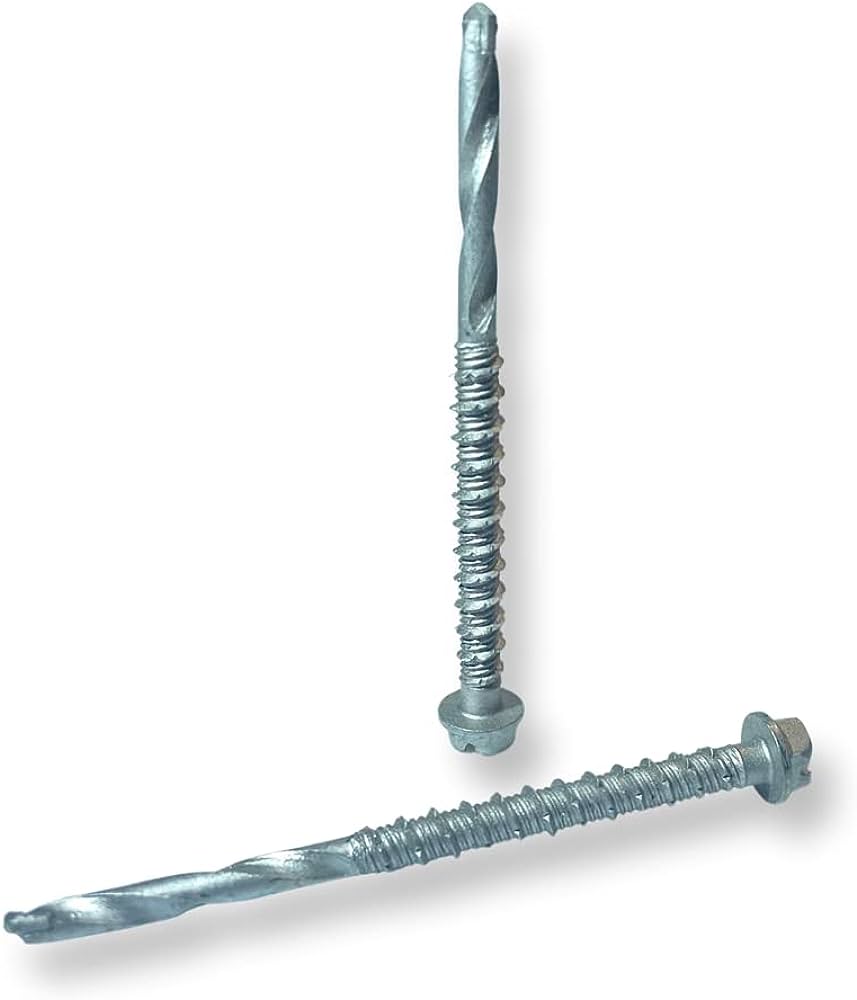

8. Self-Drilling Screws

Self-drilling screws can drill and fasten in one step, terminating the need for pre-drilling pilot holes. They have sharp, drill-like tips that easily penetrate metals, plastics, and wood, making installations quick and efficient. These types of screws and their uses in various head types, like pan, flat, or hex, fit different project requirements.

Some self-drilling screws have a self-tapping thread shape, which improves the screw’s grip and reduces the chance of slippage during installation. This is especially useful in projects involving overhead installations or hard-to-reach areas.

Self-drilling screws have a special strong coating, like zinc or phosphate, that helps them not rust and last a long time, especially when used with metal.

They’re really good for big projects with metal because they save time and don’t get loose easily, even if things are shaking. People in factories and folks who work with metal buildings like to use them a lot because they’re so handy and tough.

9. Oval Head Screws

Oval head screws have rounded heads with a slight taper towards the screw’s body. This design allows the screw to sit flush with the material’s surface when fully tightened, providing a professional appearance to decorative projects.

They are commonly used as the best screws for woodworking projects to achieve a smooth, pleasing finish, and their flexible nature makes them suitable for various applications. The shape of the head reduces the risk of tearing and ensures a neat appearance, making them ideal for furniture assembly, cabinetmaking, and other difficult woodworking tasks.

These different types of screws are also popular in industries where vibration resistance is important. Their fit and surface prevent the screws from loosening over time, making them ideal for securing parts in machinery subjected to constant motion or vibration, ensuring long-term reliability in mechanical assemblies.

10. Shoulder Screws

Shoulder screws, also known as stripper bolts, have a cylindrical body with a shoulder between the head and the threads, adding accuracy to mechanical assemblies.

The shoulder section acts as an exact spacer and shaft, allowing smooth rotation or sliding between two components and providing accurate positioning and alignment in complex machinery and mechanical systems.

These types of screws are essential for applications requiring consistent performance, such as bearings, pulleys, and rotating parts. Their strong construction and high tolerance make them important in applications requiring bearings, and rotating parts, ensuring smooth operation in high-demand environments.

The shoulder feature allows for easy adjustment and minimizes wear, increasing the efficiency and reliability of the machinery, making them required components in critical industrial systems.

11. Wood Screws

Wood screws are specially designed for use in woodworking projects, known for their reliable performance. With their sharp, threaded shaft and pointed tip, they easily seal and grip wood surfaces securely, ensuring alignment during assembly and reducing the need for pre-drilling.

These types of screws come in various sizes and types, including flat-head, round-head, and countersunk, each serving specific purposes based on the project’s requirements, catering to a wide range of woodworking needs.

Whether you’re working on furniture assembly, carpentry, or DIY woodworking projects, wood screws are the go-to choice for creating strong, long-lasting joints, guaranteeing the structural durability of your creations.

The threading on wood screws not only provides excellent holding power but also reduces the likelihood of wood splitting, making them important for building sturdy structures that stand the test of time, ensuring the longevity of your best screws for woodworking project masterpieces.

12. Carriage Screws

Carriage screws, also known as coach bolts, are heavy-duty fasteners designed with a square shoulder beneath a rounded head, conveying a distinctive appearance.

The square shoulder not only provides a smooth and neat finish but also prevents the bolt from turning once it’s installed, ensuring a secure and stable connection without the need for additional tools to hold the bolt in place.

These types of screws and their uses with both wood and metal materials often serve in applications requiring a smooth surface on one side and a threaded connection on the other, providing a tough solution for various construction and assembly needs.

Their durability ensures that structures and components remain firmly connected, even in demanding environments, making them a trusted choice in construction and engineering projects.

13. Deck Screws

Deck screws are specially crafted for outdoor decking projects, making them the ideal choice for building beautiful and hardy decks that can withstand the elements.

Their corrosion-resistant coatings effectively shield them from harsh environmental elements, such as rain and UV rays, making them highly durable and long-lasting, suitable for outdoor use and exposed conditions.

Deck screws play a deciding role in establishing a strong connection between decking boards and the underlying frame, ensuring stability over time and preventing pipes and curves in the deck’s surface.

The special coating not only protects against rust but also improves the overall aesthetics of the deck, as these types of screws are available in various colors to complement the decking material and design, adding a polished touch to outdoor spaces.

With their reliable performance and ability to endure outdoor conditions, deck screws are the go-to choice for decking projects, providing a sturdy foundation for your outdoor place and entertainment areas.

14. Drywall Screws

Drywall screws, characterized by their thin, sharp-tipped style and coarse threading, are indispensable for securing drywall sheets to studs or metal frames during the installation process. Their ability to grip the drywall material tightly to the underlying structure ensures a smooth surface, ready for finishing touches.

These screws are available in different lengths to provide various drywall thicknesses, making them adaptable for a wide range of projects. Whether you’re a seasoned contractor or a DIY enthusiast, having a reliable supply of drywall screws is a must-have for any interior construction or renovation job involving drywall installation.

15. Elevator Screws

Elevator screws, also commonly referred to as belt bolts, are strong fasteners featuring a flat, smooth head and a square neck below it. Their unique shape makes them the preferred choice for applications in transport systems and elevator buckets across various industries.

Elevator bolt screws play a critical role in attaching communicating belts to their components, providing a secure hold that withstands the demands of continuous motion and heavy loads.

In agricultural and industrial settings, these types of screws and their uses are the go-to options for securely fastening elevator buckets, ensuring smooth material handling and operational efficiency.

The square neck not only prevents the bolt from rotating during installation but also facilitates easy positioning, making belt bolts a valuable asset in any material handling setup.

16. Flange Screws

Flange screws are useful fasteners with a wide, flat, and circular base under the head. This base spreads the load over a bigger area, making the screw more stable and preventing it from getting loose due to vibrations.

They are commonly used in places where a strong joint is needed, like in cars, plumbing, and machines. Flange screws come in different materials like stainless steel, brass, and zinc-plated steel, which makes them suitable for both indoor and outdoor use.

These types of screws have jagged edges to grip better on the surface, making them more resistant to loosening in high-vibration environments. Additionally, their corrosion-resistant properties extend their lifespan and make them suitable for use in challenging conditions.

17. Set Screws

Set screws, also known as grub screws, are threaded fasteners without a head. Instead, they have a hexagonal hole for easy tightening with an Allen key.

These screws are mainly used to secure one object within or against another, often acting as adjustable stops or locating components in machines. Common uses include securing gears, pulleys, and collars onto shafts or rods.

These types of screws have different tips, like cup point, cone point, and flat point, each offering unique holding capabilities. These different tips let engineers choose the most suitable option for specific needs, like providing a strong, mark-free hold or better alignment (cone point) for rotating components. The variety of tip options ensures clarity in various mechanical applications.

18. Machine Screws

Machine screws are highly flexible and widely used in various applications, from household appliances to industrial machines. They have a consistent diameter along their entire length and come with different types of heads, like flat, round, oval, and pan. Machine screwsare usually secured into threaded holes in metal or other tight materials using nuts or threaded inserts.

They can be made from various materials, such as stainless steel, brass, or aluminum, providing strength and resistance to corrosion for specific uses.

Because of their standard thread sizes and pitch, these types of screws and their uses can be easily swapped, making them convenient for maintenance and repair tasks where quick and accurate replacements are essential.

Their reliable performance and compatibility with various materials and surfaces make machine screws an essential component in modern engineering and construction projects.

19. Mirror Screws

Mirror screws are specially designed for securely installing mirrors, picture frames, and glass items, offering capability and aesthetics in one.

The thoughtful design includes a threaded part that can be adjusted to fit different mirror or frame thicknesses, providing flexibility during installation. The rounded cap, aside from its decorative attraction, plays a crucial role in protecting the mirror’s plain surface from potential damage.

Homeowners and interior designers will appreciate the wide array of finishes available, from stylish chrome to contemporary brushed nickel, allowing them to match the mirror screws to their unique interior preferences.

Also, these types of screws for metal materials are vital, whether stainless steel or brass, ensuring the mirror screws remain hard against humidity and rust, guaranteeing longevity and peace of mind.

20. Square Head Screws

Square head screws, also known as square head bolts or coach bolts, stand out with their distinct square-shaped head that serves a practical purpose.

This design choice provides the bolts with a larger surface area, granting them superior stability and making them highly suitable for applications requiring a strong clamping force. They continue to be a popular choice in wooden construction projects, such as timber framing, where their square neck effectively prevents unwanted rotation during installation.

These different types of screws have found a place in marine and outdoor settings due to their construction from durable materials like stainless steel or galvanized steel, ensuring exceptional resistance to corrosion and harsh weather conditions.

The type of square head not only ensures easy tightening with a twist but also offers a secure grip during installation, especially in tight or hard-to-reach areas. From carpenters to DIY enthusiasts, square-head bolt screws have become a reliable and essential component for various projects.

Conclusion

Now that you’ve been introduced to these different types of screws, you’ll have a better understanding of which ones to use for your DIY projects or professional work.

Each screw serves a specific purpose, and by knowing their differences, you can ensure the right fit for your needs. These small screws are essential in our lives, holding things together and making our tasks easier.

But wait, there’s more! We explored the specialty of screws, known for their strong connections, and security screws with complex designs to keep valuables safe. These versatile screws stunned us with their ability to handle boards effortlessly, while some screws easily ruled tough surfaces like solid and hard.

From tiny electronics to towering skyscrapers, screws show us that even the smallest things can make a big difference.

So, next time you see a screw, remember its incredible impact!